News

CABINET COLD AISLE SYSTEM

Modular Data Center Solution - Cabinet Cold Aisle SystemThe modular data center solution - the cabinet cold channel system is the mainstream and leading application solution in the industry today. It is widely used in large, medium and small computer rooms in various industries and is highly recognized by industry experts and users.

In line with the development trend of today's data centers (IDCs), Huaxin Dongyuan has launched a new generation of data center solutions for medium and large data centers that are built on demand and gradually expanded. It provides complete infrastructure solutions for IT applications in education, medical care, manufacturing, government, finance, commerce and other industries, and realizes rapid construction, flexible expansion and simple management of data centers.

Overview of Rack Cold Aisle

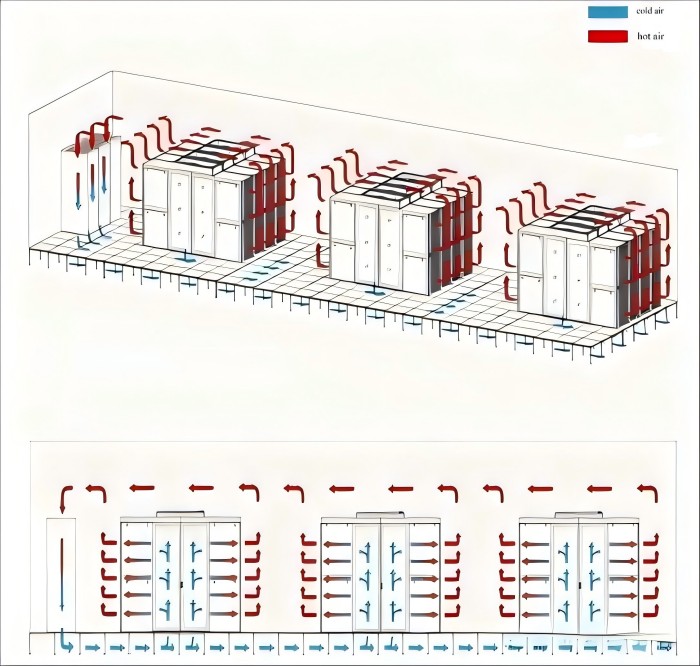

At present, most data center cabinets are arranged with a hot and cold channel separation design. The advantage of this design is that it roughly distinguishes between hot and cold air, and has a better cooling effect than the more backward hot and cold channel staggered design. However, since the hot and cold channels are not completely closed, the cold and hot air will still be mixed at the end or top of the cabinet row, which will lead to two problems: the cabinet inlet air temperature increases and the air conditioner return air temperature decreases. The increase in the cabinet inlet air temperature will lead to a waste of air conditioning cooling, affecting the cabinet heat dissipation, and affecting the cabinet heat dissipation; the low air conditioner return air temperature will lead to a decrease in air conditioning efficiency.

The simplest and most effective way to solve these two problems is to adopt a closed cold channel solution, as shown in the figure below.

Cold/hot aisle containment system

Cabinet cold aisle layout

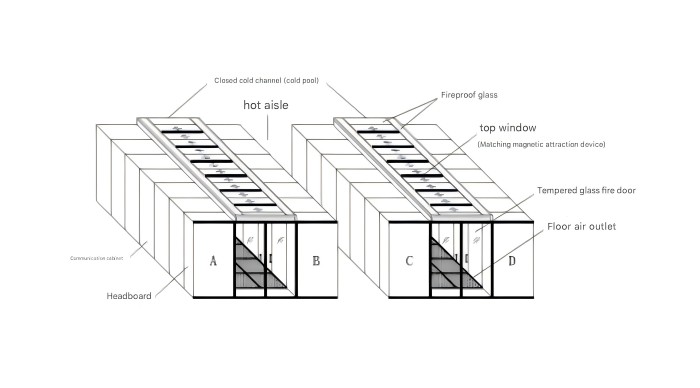

The cold channel cabinets in the computer room are arranged face to face and back to back, and the front (air inlet) of the two rows of cabinets are enclosed in a channel. The channel width is generally 1200mm or 1800mm (i.e. the distance between the two rows of cabinets facing each other) to form a cold channel and a hot channel. The top above the two rows of cabinets is closed to form a cold pool. The cold channel is the front area of the two rows of cabinets, and the hot channel is located at the back of the cabinet. The cabinets are arranged opposite to each other on both sides of the cold channel, and the cold air is blown out from the exhaust vents of the raised floor panels. Since the top of the cabinet is closed, the cold air will enter from the front of the cabinet, pass through the equipment in the cabinet, and be discharged from the back of the cabinet to achieve a full equipment cooling effect.

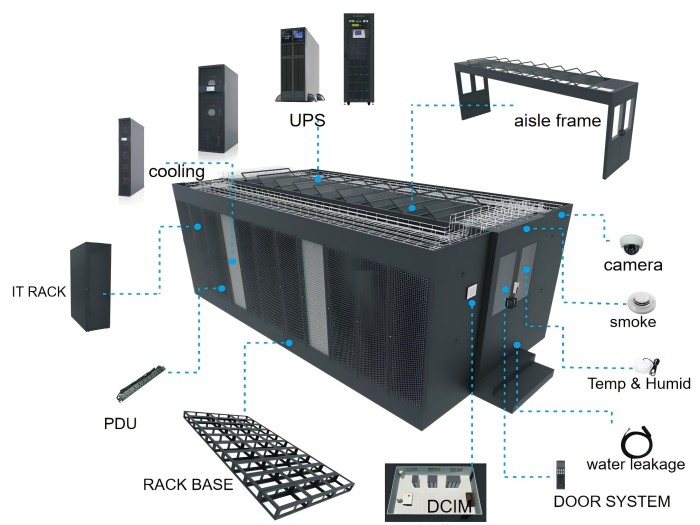

Composition and integrated solution of cabinet cold channel

Main components of cold channel structure

Cabinet

Closed cold pool system

Row air conditioning

Cable duct

Display cabinet

Dynamic environment monitoring system

Electrostatic floor and other auxiliary systems

Closed cold pool system

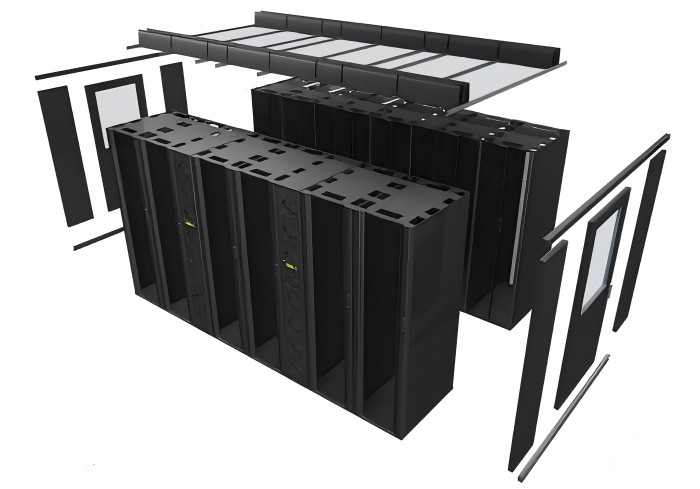

The closed cold pool is mainly composed of the following components: glass skylight components, glass isolation door components, steel false wall components, fire linkage system components, and environmental monitoring unit components.

Features:

Achieve isolation of hot and cold channels and make reasonable and effective use of cooling capacity

Prevent cold and hot from crossing and causing cold loss.

Changed the traditional situation of cooling the environment first and then cooling the equipment

Make rational use of resources and save electricity.

Provide a very stable working environment for the equipment.

Glass sunroof components

According to different installation requirements, there are three types of skylights to choose from: movable skylights (also called flip skylights), functional skylights and fixed skylights. In this solution, the fire gas pipeline is located on the top of the machine room, so movable skylights and functional skylights are selected.

Active sunroof

It is suitable for installing fire-fighting gas pipelines on the top and can be linked with the fire-fighting system. When an abnormality occurs inside the cold channel, the temperature is too high or there is smoke and fire, the skylight will open automatically and the fire-fighting gas sprayed by the fire-fighting system can be quickly sprayed into the channel to avoid fire. The "double-flip skylight" has a completely downward structure when the double-flip skylight is flipped, so it does not occupy the space above the skylight. It is particularly suitable for low-rise scenes and scenes with low floor heights in some locations due to the presence of beams.

Double flip skylight

Functional skylight

Used to install power supply, temperature and humidity sensors, smoke detectors, cameras and fire linkage control units, etc.

Glass isolation door components

The whole channel door is connected to the frame by screws, and a sealing brush is installed at the bottom of the door panel to ensure the airtightness of the sealed channel system. The end door is a left and right double-opening structure, with a large area of transparent tempered glass in the middle of the door leaf, which is normally closed.

There are 3 ways to open the passage door:

Automatic sliding double doors (automatic opening function in case of power failure)

Manual sliding door

Manual double door (door axis rotation opening)

Fire linkage system components

Movable sunroof power supply: main and standby two-way input, providing stable voltage to the sunroof electromagnetic lock.

Magnetic lock for movable sunroof: locks the movable sunroof, adsorbs the sunroof when powered on, and opens automatically when powered off.

Sunroof drive system

Drive the sunroof to open. When the fire protection system or monitoring system provides an abnormal signal to the drive unit, the drive unit controls the sunroof through a relay and cuts off the power to open.

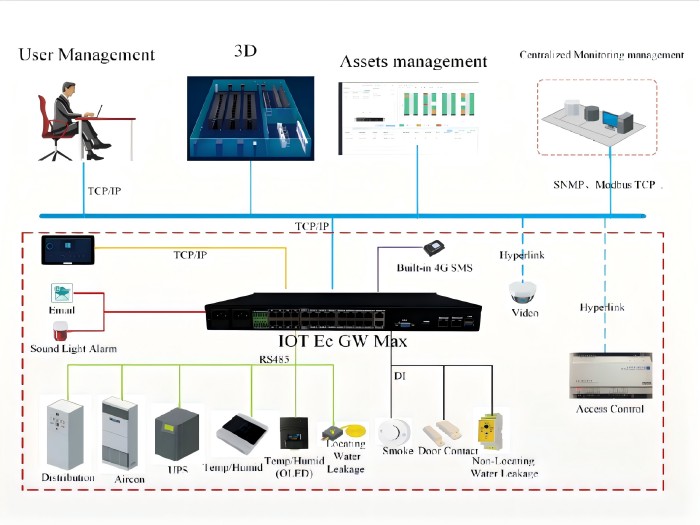

Environmental Monitoring System

Monitoring Host

The micro modular data center management system monitoring host is a new generation of monitoring host, which supports multi-point touch screen, has good human-machine interface and touch performance, and provides a full set of configuration software development tools. It does not require programming and can quickly realize data collection, graphical display and centralized IoT monitoring management of the monitored objects. It supports networking of multiple devices, which is convenient for management and has rich functions, such as alarm linkage and SMS alarm.

Features

Standard 19-inch rack installation, 1U height, ultra-low power consumption

The monitoring host software and hardware are integrated and highly integrated

Adopt B/S architecture, no need to install client software

Support electronic maps, 3D configuration diagrams

Automatically generate performance reports on computer room equipment, computer room environment, etc.

Supports alarm modes such as sound and light, telephone voice, SMS, and email

Support mobile phone, tablet computer multi-terminal APP browsing, WeChat public account browsing

CATEGORIES

LATEST NEWS

CONTACT US

Name: Andy Zhou

Mobile:86 198 0409 1024

Tel:86 198 0409 1024

Whatsapp:8619804091024

Email:sales@datacenterstech.com

Add:Wusi Road NO 4399 Haiwan Town Fengxian,Shanghai,China