News

LIQUID COOLING CONTAINER SYSTEMS

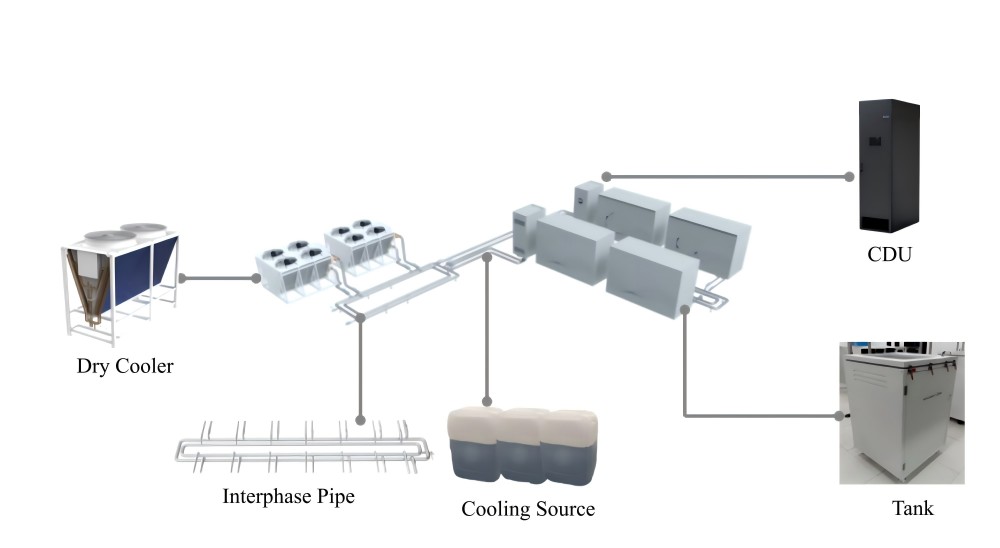

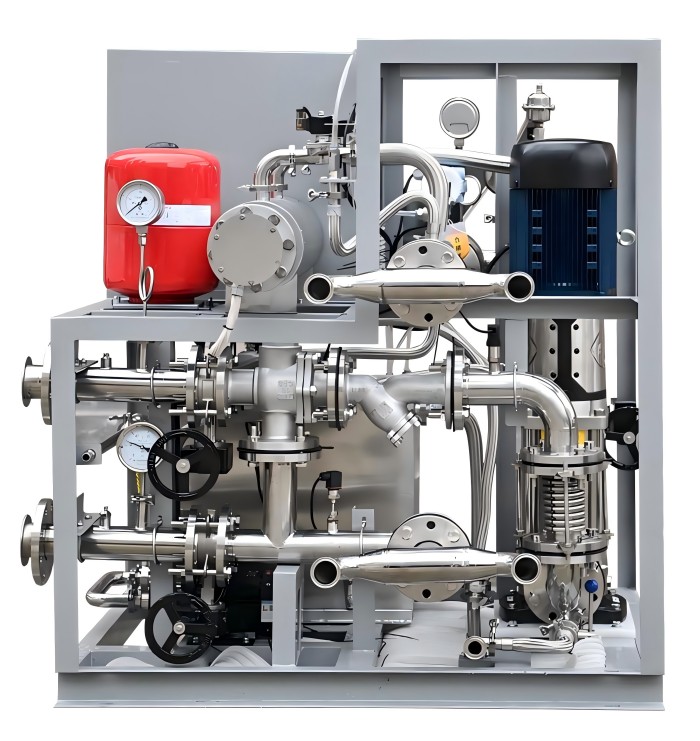

Liquid Cooling Container SystemsLiquid-cooled container-type cold plate/immersion air-cooled dry cooler V-shaped vertical dry cooler cooling tower 40-foot container-type 1MW 2MW cooler radiator detailed introduction

More and more data centers use immersion cooling systems to replace traditional air-cooled air conditioning systems. The dry coolers produced by our company are the main components of single-phase and two-phase immersion cooling systems.

Application Features

1. High efficiency heat exchanger

1. Reasonable design reduces fan loss while obtaining heat exchange

2. Reasonable copper tube design reduces the pressure drop of the medium in the coil

3. Our thermodynamic and kinetic design software has been used in Germany for many years and has been fully verified by the market.

1. Choose low energy consumption fans

2. Reasonable fan nozzle design can increase air flow and reduce noise

3. Practice has proved that our fans are stable and have a long service life

4. Motor waterproof and dustproof level: IP54, insulation level: F

5. Each fan is a partitioned chamber

1. Help customers reduce maintenance and increase product life

2. High quality galvanized steel powder coating shell

3. Add side panel protection devices on both sides

4. Reasonable design is conducive to outdoor installation

5. Each product is leak tested at 31 bar

4. Special processing

1. Coils with different media such as water, oil can be designed according to customer requirements

2. Multiple circuits

3. Subcooling circuit

4. Stainless steel housing or aluminum housing

5. Aluminum fins or copper fins

6. Explosion-proof motor

7. Specify the film spacing

1. Relative humidity 40%

2. Atmospheric pressure 1 bar

3. 20% ethylene glycol, water, design ambient temperature 35 degrees Celsius

6. Application

Industrial air conditioning, process engineering, process cooling, heat dissipation/power stations, it is suitable for all equipment that requires heat dissipation and is installed in the open air.

The indirect natural cooling system of the computer room air conditioner consists of indoor units, outdoor dry coolers (or cooling towers) and water pumps. The system automatically switches modes through the computer room air conditioner controller according to the outdoor temperature and load. The higher the set indoor return air temperature, the longer the natural cooling time using outdoor fresh air can be.

Tips: Taking the indoor return air temperature set at 27℃ as an example, when the outdoor temperature is lower than 24℃, natural cooling can be started and the system can enter mixed mode operation.

Air Cooling Design Principle of Glycol Dry Cooler

The glycol dry cooler heat exchange system uses the indirect use of natural cold sources, also known as natural cooling energy-saving air conditioners. The outdoor dry cooler is used to exchange heat with the outdoor air, and the glycol aqueous solution is used as a coolant to provide a cold source for the energy-saving coil of the indoor unit to reduce the temperature of the machine room. The unit is controlled by a microcomputer. When the glycol return water temperature differs from the machine room temperature by 7°C, the natural cold source can be partially utilized, and the insufficient part can be supplemented by compressor refrigeration. When the above temperature difference is above 14°C, the dry cooler can completely replace the compressor refrigeration to achieve the purpose of energy saving.

Natural cooling air conditioners use the low freezing point of ethylene glycol aqueous solution as a refrigerant for refrigeration and cooling in winter. The higher the concentration of ethylene glycol aqueous solution, the lower its freezing point, so when it is used, the concentration of ethylene glycol solution should be adjusted according to the lowest temperature in the local winter. The specific heat of ethylene glycol aqueous solution is less than that of water, and its specific heat will further decrease as its concentration increases. The concentration of ethylene glycol solution in winter for natural cooling special air conditioners is generally 30%, at which time its freezing point is -28℃ and its specific heat is 3.412KJ/KG·℃. When used in the Northeast region, the ratio concentration of ethylene glycol is 50%, at which time its freezing point is -35℃ and its specific heat is 2.931KJ/KG·℃. It can be seen that the ratio concentration of ethylene glycol solution affects its heat exchange capacity. The heat exchange capacity of ethylene glycol solution and dry cooler can be calculated according to the heat transfer calculation formula.

CATEGORIES

LATEST NEWS

CONTACT US

Name: Andy Zhou

Mobile:86 198 0409 1024

Tel:86 198 0409 1024

Whatsapp:8619804091024

Email:sales@datacenterstech.com

Add:Wusi Road NO 4399 Haiwan Town Fengxian,Shanghai,China